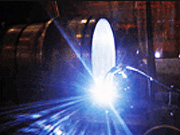

Welding

Metal Surgery uses qualified personnel to perform all welding in the following welding modes:

- SMAW – Shielded Metal Arc Welding.

This is a manual welding process, and the quality of weld depends on the skill of the welder. For this reason, the welder must be proficient and the procedure used must be correct. - GTAW – Gas Tungsten Arc Welding.

This is an arc welding process that uses an arc between a tungsten electrode and the weld pool. An unpressured gas flow is used to shield the welding arc and molten weld pool from air contamination. - GMAW – Gas Metal Arc Welding.

This is an arc welding process that uses an arc between a continuous filler metal wire and the weld pool. Shielding is accomplished with an externally supplied gas. - FCAW – Flux Cored Arc Welding.

This is an arc welding process that uses an arc between a continuous filler metal electrode and the weld pool. Shielding is accomplished by the use of a flux contained within the tubular electrode, with or without additional shielding from an externally applied gas. - SAW – Submerged Arc Welding.

This process produces coalescence of metals by heating them with an arc between bare metal electrode and the work. The arc and molten metal are submerged in a blanket of granular fusible flux on the work.

Process Standards covering all aspects of welding projects are composed and issued by the plant metallurgist, e.g., codes, modes, electrodes, shielding gas, preheat, postheat, etc.

Air carbon arc, grinding and chipping tools are used to remove defective areas and prepare cavities for welding.

Preheat and postheat are accomplished using torches or electrical ceramic heating pads. The ceramic heating pads are unique in that they can be used on isolated welded areas without heating the entire component. With the ceramic heating pads, structures can be easily stress-relieved on-site or in plant.

The inspection techniques of magnetic particle and liquid dye penetrant are available as quality tools.